Links:

-

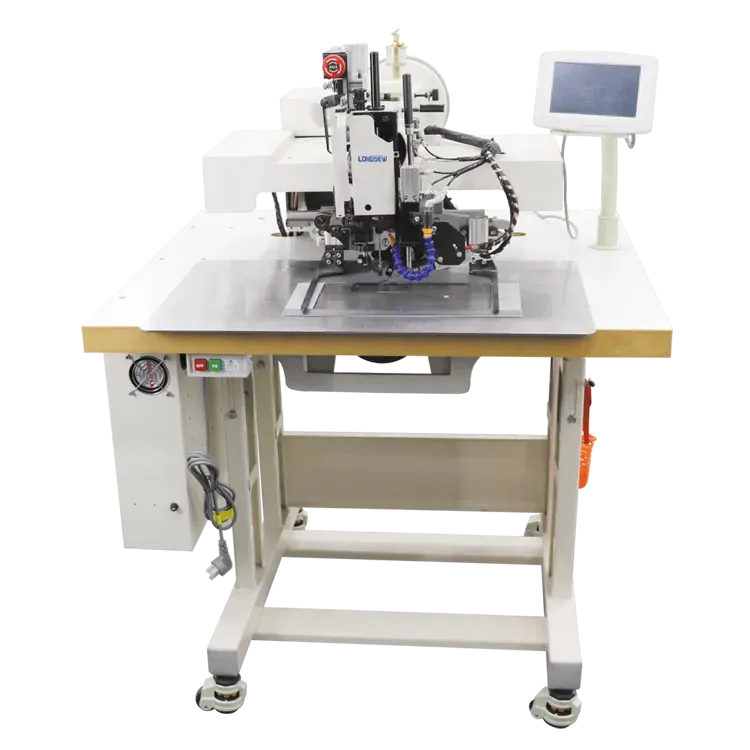

In addition to its versatility, the Cub Leather Sewing Machine is also extremely user-friendly

cub leather sewing machine. With its easy-to-use controls and clear instructions, you will be able to start sewing with confidence right away. Whether you are a seasoned leatherworker or just starting out, the Cub Leather Sewing Machine is perfect for crafters of all skill levels.

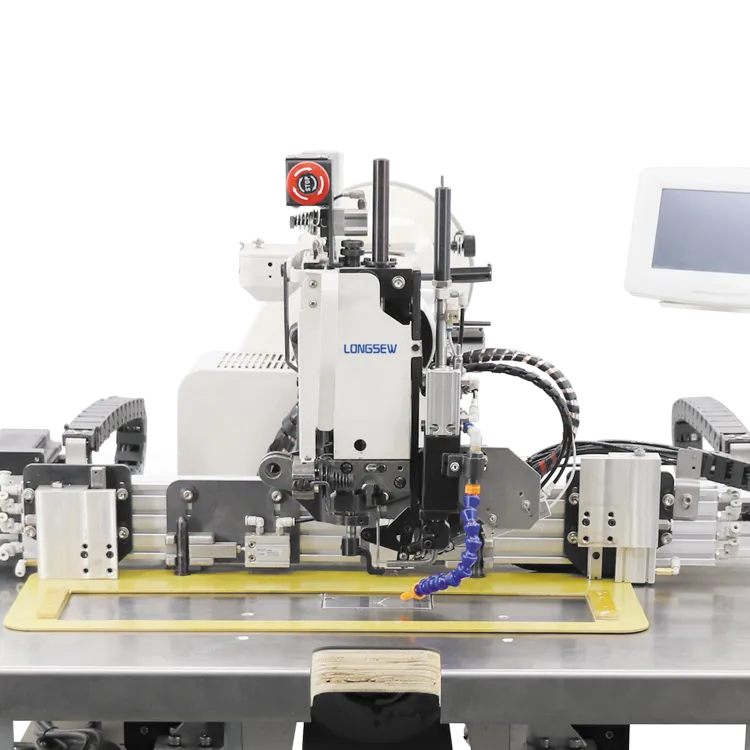

1. Versatility The double needle setup allows for creative stitching designs. You can create beautiful pintucks and decorative hems that add unique detailing to any project. This makes it an excellent choice for fashion designers looking to add flair to their collections.